Making your Product

We provide all steps out of our team internally. You find all of the steps under one roof of our 2000 sqm industrial building near Berlin- just 5 minutes of walkway from the S-Bahn S5.

Product Design

After listening to you and learning about your market requiremtns, we design products for...

Development

More and more we see that the materials along with the geometry itself are the deciding factor for success...

Design and making

We internally design and provide mold making capabuility and capacity for both Thermoplast Molds...

Serial Manufacturing

Once the project is successfully completed, everyone is waiting for the first series to arrive. We as Römmler team...

Service

Product Design

After listening to you and learning about your market requirements, we design products for specific applications. We assist your Engineering team or design from first concepts to the final solution. Medical devices which are part of our own product lines are designed internally.

Molded parts

Spuni

Medical devices

Testing devices

Specialized in

Material development

More and more we see that the materials along with the geometry itself are the deciding factor for success in the markets we operate in.

The Römmler team is setup to help you and your team haveing the rigth properties for your final product resting on solid material formulations. Our team has a long history of developing material formulations for composite materials in thermoset applications (SMC / BMC) and alike speciality powders based resins like Melamin or Urea. We help to select the rigth Termoplasts for the applikativ in scope and are familiare with high end Engineering resins from usual Polyamides to PPS / UDL / LCP and alike. We do develop thermoplast combinations for bio intert requirements according DIN EN ISO 10993-1 and are familiare with the MDR driven homologation process.

Specialized in

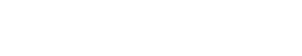

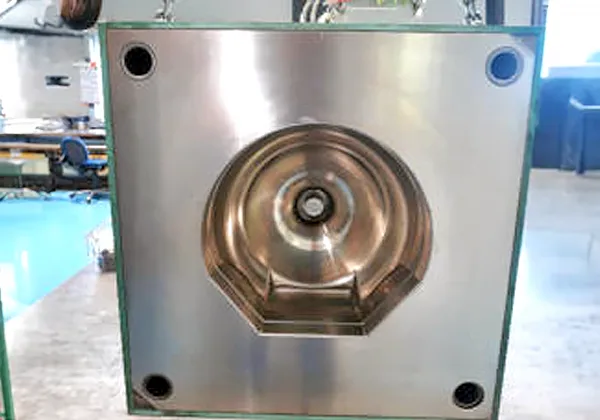

Mold + Equipment design and making

More and more we see that the materials along with the geometry itself are the deciding factor for success in the markets we operate in.

As we manufacture Thermoset materials for more than 125 years, we still have a dedication towards Molds for this special area. Processing of unsatisfied Polesters and Epoxy composite have become part of our DNA, so we successfully building Molds for this special field.

We internally design and provide mold making capability and capacity for both Thermoplast Molds, Thermoset Molds as well as all assembly equipment to move from the individual components to product or modules. We have all capabilities inhouse and provide a fully blown CAD and CAM / CNC platform to establish the equipment. Our maximum Mold sizes range up to 1.000 kg Molds.

The processing of unsatureated Polyesters and Epoxy composite have become part of our DNA and so we have been building Molds for this special field with success and loads of learnings. The largest Mold we have been building was to accomodate Li / Ion Accu cells for Trucks.

Duro Molds + Thermoset for composite processing

The largest Mold we have been building was to accomodate Li / Ion Accu cells for Trucks. With our internal Toolroom team and equipment, we can support all maintenance activities for all Molds and machinery which assures that your assets remain intakt.

On top, we consider this capabuilit the core of risk mitigation assuring you as customer On Time Delivery. And yes, we do have a network of partners in Asia who help us to bring the best / most effective solution to the starting line of your project. This network is ranking based and handles cost sensitive projects under our supervision.

Thermoplast Molds

Our speciality on Thermoplast Molds is the so called „cassette Mold“ approach. Allowing you and your project team to save some invest as the frame of this particular Mold is already existing and gets shared among many applications.

Our experience over more than 8 years shows that there is no compromise on both efficiency or life cycle using this technology.

As we manufacture Thermoset materials for more than 125 years, we still have a dedication towards Molds for this special area. Internally, we build Molds for heat transfer pressing and injection of thermoset resins.

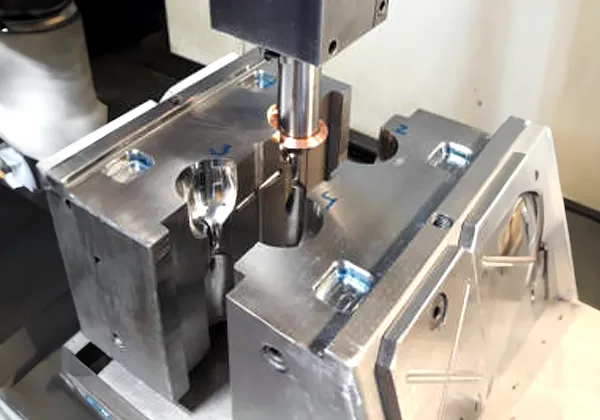

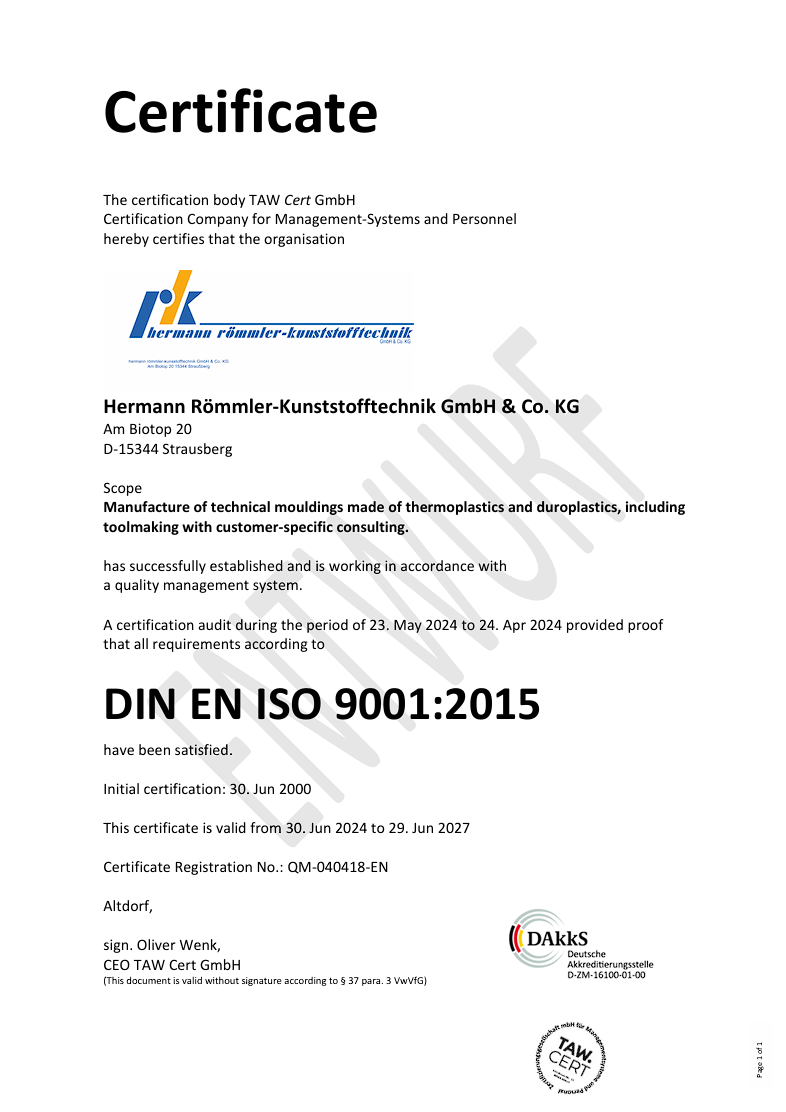

Product homologation

Not all products- but many have the requirement to be managed via startup processes (e.g.PPAP). So we are setup to deliver all required formats of homologation data and documentations.

As serial production is moving on and the focus of the implementing team shifts- we maintain all of the „froozen documents“ to never loose the baseline. So you have the confidence to get both, up to date product and current data.

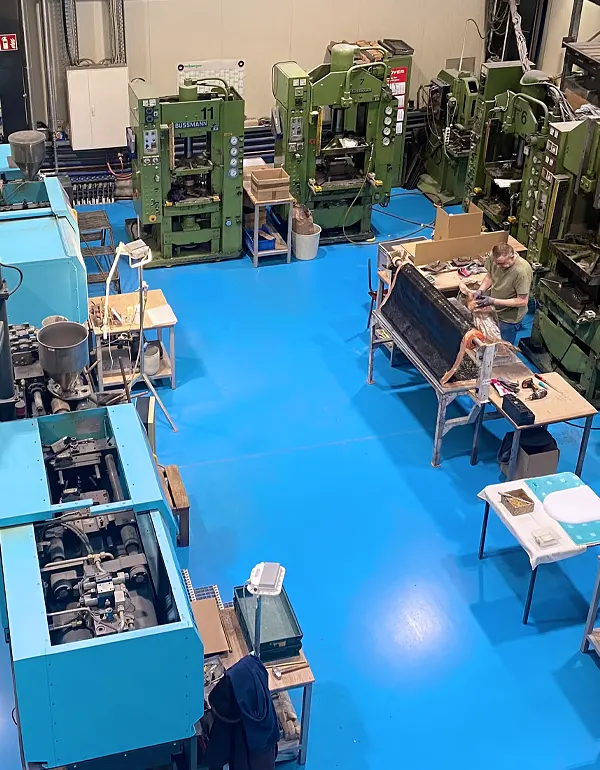

Serial manufacturing

Once the project is successfully completed, everyone is waiting for the first series to arrive. We as Römmler team are setup for make to order from small to mid size and larger scale manufacturing of Thermoplast product as well as Thermoset / Duroplast product. This batch manufacturing does not stop at the making machine, we also provide assembly / printing and many other subsequent operations. We operate 24 hours and 5 day per week in Germany. We do operate an fully equipped thermoplastic molding operation providing machinery and equipment which is state of the technology ranging from 35 tons to 275 tons of clamping force. The maximum shot weigth is appr 1.000 gramms of polysterene equivalent. Theromset and composite operations are located in the same building and provide pressing capacity ranging from 20 ton up to 320 ton and covering projected area for parts of max 800 mm x 600 mm. For powder or other pourable materials we running injection machinery dedicated to Theroset / Duroplast resins out of the phenol / Melamin or urea family.